Dating back to the 1950s, disc brakes have undergone constant development and improvements to become what they are today. With braking power and are high reliability in dry or wet weather, disc brakes can commonly be found on many mountain and off-road bicycles.

A disc brake consists of a metal disc or rotor attached to the wheel hub that rotates with the wheel. Brake calipers are attached to the fork along with pads that squeeze together on the disc when the brake levers are applied.

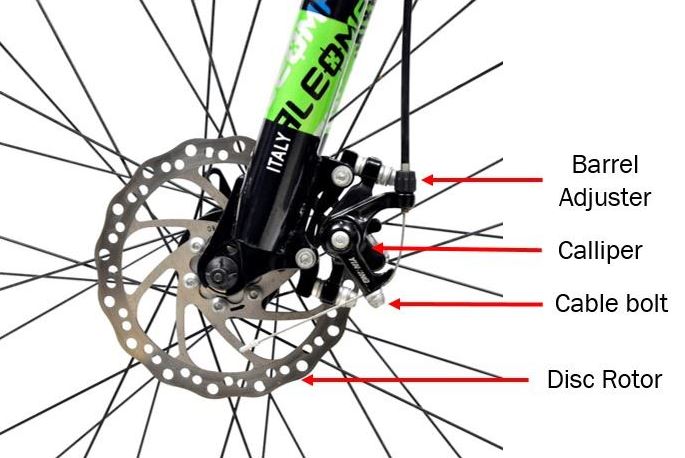

A cable disc brake on an Aleoca FXTD Mountain Bike

This post will cover the common issues with cable disc brakes and how to tune them for optimum braking performance — starting with the different parts and how they work.

This post will cover the common issues with cable disc brakes and how to tune them for optimum braking performance — starting with the different parts and how they work.

Important parts of disc brakes

How they work:

How they work:

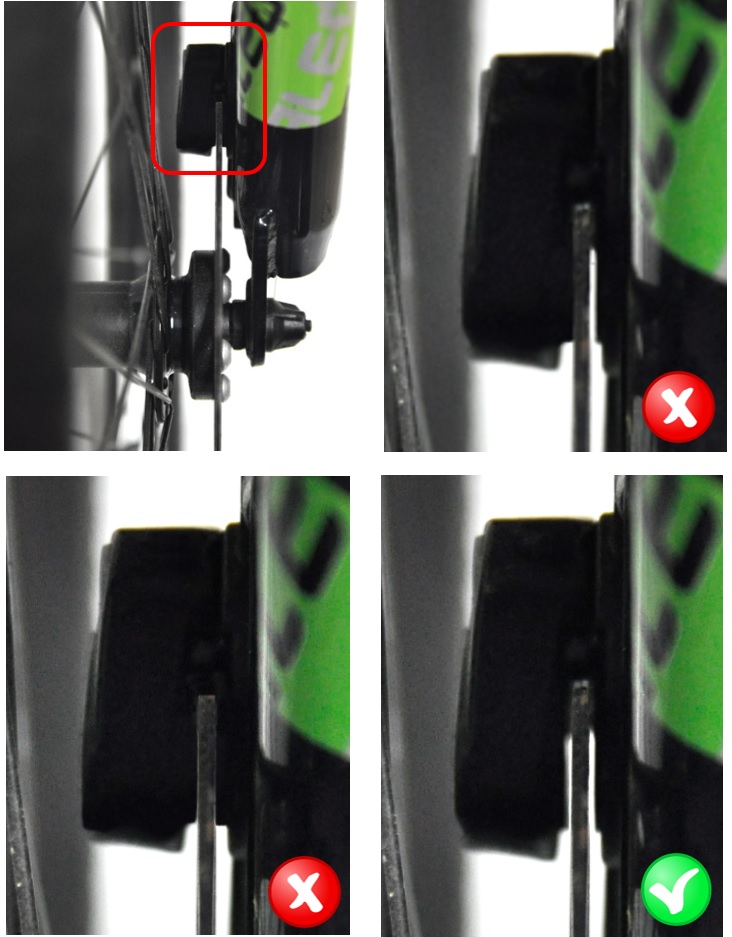

Cable disc brakes are activated via cable pull from the brake levers. When the brakes levers are depressed, the cable disc caliper only causes one side of the brake pad to move inwards and clamp onto the disc rotor. In later steps, the non-moving brake pad is able to be adjusted via the limit adjuster. Common issues with disc brakes include the brakes feeling loose and a loud squealing noise while rolling. When the brakes are not engaged, the brake pads should not be touching the disc rotor. The pictures below show the ideal clearance that the brake pads should have from the disc.

Common issues with disc brakes include the brakes feeling loose and a loud squealing noise while rolling. When the brakes are not engaged, the brake pads should not be touching the disc rotor. The pictures below show the ideal clearance that the brake pads should have from the disc.

The following steps will help rectify:

The following steps will help rectify:

– Disc Calipers that are uneven or rubbing the disc

– Disc Brakes with poor stopping power

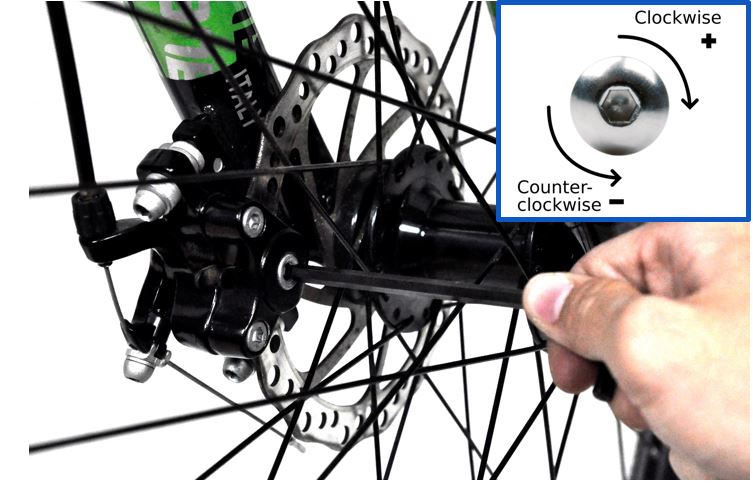

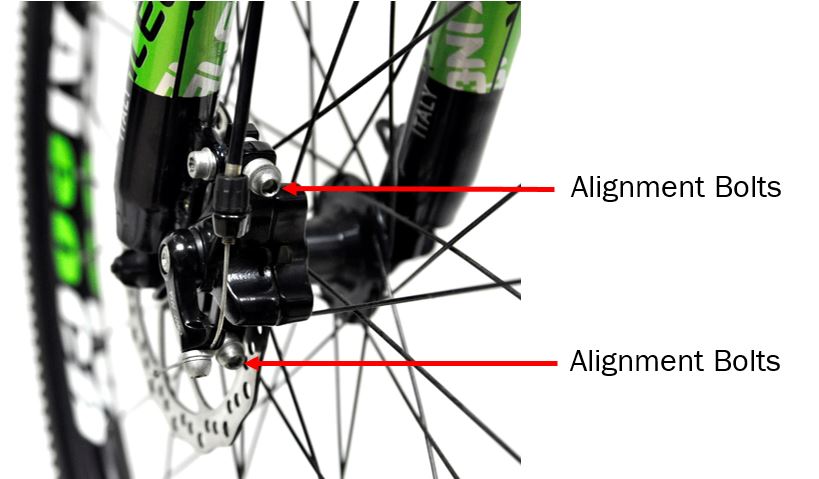

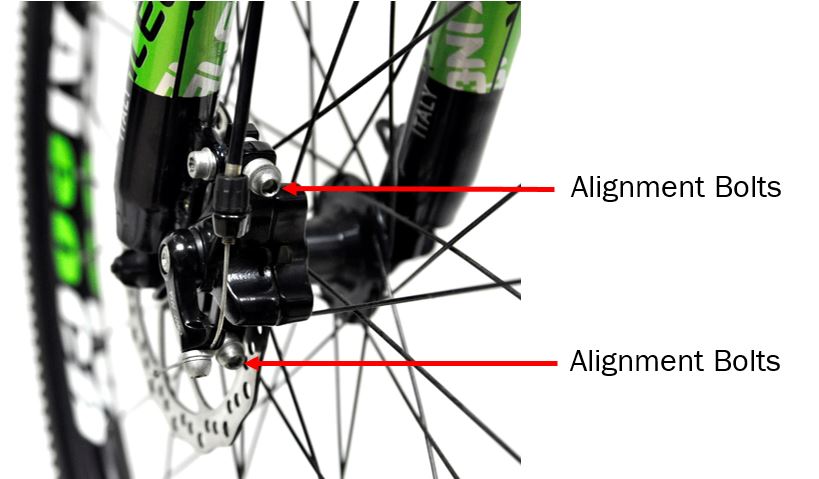

Step 1: Loosening alignment bolts

This step allows you to set the brake caliper alignment and ensure that the brake pads do not rub the disc.

These alignment bolts help hold the entire disc brake caliper in place.

These alignment bolts help hold the entire disc brake caliper in place. Using an Allen key, turn the bolts anticlockwise to loosen until the caliper can be moved.

Using an Allen key, turn the bolts anticlockwise to loosen until the caliper can be moved.

Step 2: Setting the caliper position

With the caliper bolts loosened and able to move, fully depress the brake lever so that the brake pads are engaged. This will help align the caliper and set the brake pads evenly apart.

When the brake lever is fully depressed, the caliper arm should move upwards due to the brake cable pull.

When the brake lever is fully depressed, the caliper arm should move upwards due to the brake cable pull.

With the brake lever still fully depressed, tighten the adjustment bolts by turning them clockwise to fasten the caliper back in place.  After tightening both adjustment bolts, release and test the brakes once again. The caliper will be set at the correct position (no unevenness) and may require some more fine tuning adjustments for perfect braking.

After tightening both adjustment bolts, release and test the brakes once again. The caliper will be set at the correct position (no unevenness) and may require some more fine tuning adjustments for perfect braking.

Step 3: Fine tune adjustments for cable tension

Fine tune adjustments will make smaller changes to the brake pad position to eliminate any sounds or rubbing.

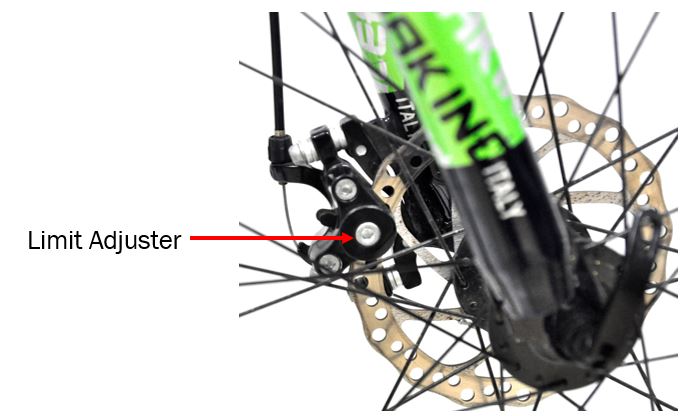

Limit Adjuster

The limit adjuster is found on the inner side of the disc brake, in between the fork. This bolt helps adjust the position of the inner brake pad that does not move. Turning this bolt clockwise will make the inner brake pad move nearer to the disc. Turning this bolt anticlockwise will make the brake pad move further away from the disc.

Make small adjustments to ensure that the inner brake pad does not touch or rub against the disc.

Brake Cable Tension

Similar to other braking systems, disc brakes rely on cable tension to be activated.

The sensitivity of brakes levers differs to each individual. As a guide, it is recommended that the brakes should be engaged when the levers are depressed half way.

To increase the cable tension of your disc brakes, first loosen the cable bolt on the calliper. Turn anti clockwise using an Alan key to loosen the bolt.

With the cable bolt loosened, push and engage the caliper arm upwards and at the same time pull the brake cable wire downwards.

After pulling the excess wire, hold the position of the caliper and tighten the bolt back in place.

Test and depress the brake lever to determine if tension is sufficient.

Test and depress the brake lever to determine if tension is sufficient.

Barrel Adjuster

Turning the barrel adjuster will also make fine tune adjustments to the brake action.

Remember to check that all bolts are tightened properly and that parts are aligned and in good condition before going out for your ride!